Introduction:

As of recent years, the offer on power LEDs has broadened and this technology seems to have a bright future in our lives replacing the incandescent light bulb. I have decided to write this article about the ways to powering LEDs because many people have asked me what type of circuit they could use.

Compared to light bulbs, LEDs are a little bit more complex. When you need a light bulb, you buy one with the appropriate voltage given by your power source and the required power depending on how much light it has to give. Things are rather simple.

With LEDs it is a more complicated. First, they are not linear devices. A light bulb is mostly like a resistor when you are close to its normal operating point. If you apply 10% more voltage, you get 10% more current through it and it consumes 21% more power. LEDs, as their name implies, are basically diodes. And diodes are nonlinear. The current that passes through them depends exponentially on the voltage applied. Therefore, if you apply 10% more voltage to a diode, chances are you might get even 100% more current. This can be expressed as: the current through the LED varies in a wide range for a very low voltage change or the voltage across the LED varies in a low range for a high variation of the current. You can observe this from the diode characteristic, I recommend reading the wiki on LEDs.

As you can see, the voltage needs to be higher than a threshold in order for the LED to conduct. This is the minimum voltage that the LED needs in order to produce light. From further on this article will assume that the LED voltage is at least this value, thus it is on and it emits light. There’s no point in talking about turned off LEDs, is it?

Due to physical reasons which I will not discuss here, the amount of light a LED gives is dependent on the current that flows through it. Therefore the current is the parameter that needs to be controlled when powering an LED. And this is where the problems start. A battery gives you a constant voltage (well it varies depending on load and charge, but it’s a voltage that it gives you). A power supply gives you a constant voltage. Therefore a circuit is needed that can supply the constant current required.

All this circuits presented are well known and had been around for a long time, being used in many applications such as amplifiers, my goal being only to gather here as many of them as possible. The explanations are short and I assume you are familiar with basic operations of various components and different laws. Also, for simplicity I have chosen to show single LED on the schematic, but more LEDs connected in series can be used instead. Therefore, let’s look at different options, starting with linear circuits:

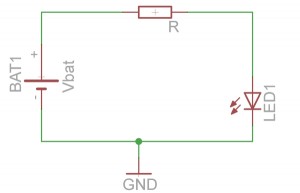

Using a series resistor:

This is the simplest circuit. A resistor in series with the LED limits the current. In order to calculate the value of the resistor R we need to know what current is needed through the led, the voltage across it at that current and the supply voltage:

R = (Vbat – VLED)/ILED.

Or, going around the other way, the current through the LED can be expressed as:

ILED = (Vbat – VLED) / R.

As we discussed, the voltage across the LED varies a little for a broad range of currents, therefore we can consider VLED a constant. So is R. So the current through the LED is now dependent only on the battery voltage, Vbat. If you power the LED from a battery or any other supply that is not well stabilized the voltage given will vary, and so will the current through the LED which is an undesirable effect. This circuit is generally used where LEDs are indicator lights, such as whether a device is turned on or not. The variation of light output depending on voltage is in no way critical here. This circuit is not suitable for using with high power LEDs that are used for lighting; still you may find it in many low cost flash lights. Even more, some very low cost devices even omit the resistor and rely on the actual internal resistance of the battery. This is usually very uncontrollable and depends quite a lot on the battery used. The low quality battery that the manufacturer has installed has a high enough internal resistance not to cause a too high current. But if you swap it for a good quality alkaline with a much smaller internal resistance a very high current will pass through the LEDs in the flashlight. This will cause them to have a very short life. Don’t ever connect a LED directly to a battery!

One transistor constant current supply:

This is probably the simplest circuit that is able to provide a constant current for a led.

This is how it works: diodes D1 and D2 and R1 provide a fixed voltage of 1.4V. The same voltage drops on the BE junction of T1 and RS together. As the BE junction is a diode too, 0.6V will drop on it. This leaves 0.6V for RS. So in order to set the current through the emitter of the transistor (and through the led) you need to calculate RS. The current through the LED is:

ILED = 0.6/ RS.

Or, if you want to calculate RS = 0.6/ ILED. Say that you need to have 350mA through the led, you calculate RS = 2Ω and the closest available common value is 2.2Ω. One more thing needs to be calculated. This is R1. . Its value is not that critical, it must be able to supply enough current through the transistor’s base and for the diodes. The current through the base of the transistor depends on the current through the led, and it is β times smaller. After choosing the transistor, the amplification factor β can be found in the datasheet. Assuming it is 50, you will need 350mA/50 = 7mA through the base. If we allow 1mA through the diodes a total of 8mA is needed. To calculate R1 the lowest possible value of the power supply is needed, let’s say Vbatmin = 6V. Therefore R1 = (6– 1.4)/7mA = 657Ω. We choose the next smallest value available, say 560Ω. As I mentioned, the value is not critical, just use a smaller one that given by the math.

In order for the whole circuit to function properly, the input voltage given by the power supply needs to be at least 1V higher that the voltage required for the led. This is because 0.6V will drop on RS and at least 0.3V will drop between the Collector and Emitter of the transistor. So, roughly 1V higher is needed.

This circuit is a linear power supply; this means that the transistor will drop almost (except 0.6V that falls on the resistor) all the difference between the power supply voltage and the LED voltage. This causes it to dissipate power, PT1 = (Vbat – VLED) * ILED, roughly. Choose a transistor that is able to dissipate at least 50% more than you calculate. And make sure that you cool it with sufficient heat sinking.

The power dissipated on RS is Pr2 = 0.6 * ILED. Again, choose a resistor that is capable of dissipating more than this, I recommend at least double.

Now let’s have a look at a similar circuit.

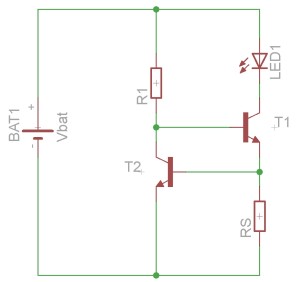

Two transistor constant current supply:

The principle of operation is somewhat different, but still simple. If T2 would not be there, R1 would provide enough current to fully open T1. That would not limit the current through the LED. But once T2 is in place, when the voltage across RS reaches 0.6V it opens and starts consuming the current that R1 supplies, leaving less for T1. This ensures that the voltage across RS is always 0.6V, which means that the current through the LED is ILED = 0.6/ RS, therefore constant. The same rules as before apply for T1, RS, and R1. T2 generally needs to be a low power transistor, e.g. BC547.

One advantage of this circuit is that mounting T2 on the heat sink used by the LEDs can provide some thermal compensation; the current through the LEDs will decrease as they get hotter.

Another advantage of this circuit is that you can replace T1 with a power MOS transistor:

Functionality is the same, only that M1 doesn’t need a Gate current to operate, thus the current through R1 is smaller, I recommend setting it around 1mA, but that is not critical. Also, the voltage drop between the Drain and Source of the MOS may be a lot less, depending on the ON resistance of the transistor and the current through the LED. Say the current through the LEDs is 350mA and the ON resistance of the MOS is RON= 0.1 ohms, then only 35mV will drop between Drain and Source, meaning that Vbat requires to be only 0.6-0.7V higher than the required voltage for the LED.

Additional functionality:

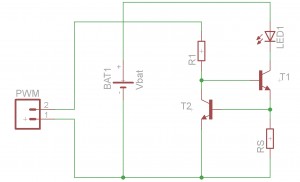

The last 2 circuits can be modified to be controlled by a microcontroller, such as for providing PWM control.

Schematic requires only minor modifications, as it can be seen below:

PWM signal can be applied through R1, which needs to be calculated the same as before, but taking into account the voltage given by the microcontroller (for example 5V).

Using LM317

LM317 is a widely used voltage regulator, but it can also be used as a constant current source. The schematic comes from the datasheet, the operating principle being very simple. As the regulator will try to maintain 1.25V between Out and Adj pins, the current through RS will be constant, and equal to ILED = 1.25 / RS.

As the datasheet recommends, the input voltage should be at least 3V higher than the output voltage. Adding this to the 1.25V dropped on RS, this means that the input voltage should be at least 4.25V higher than the voltage required for the LED. This is quite a lot and makes this circuit rather inefficient. Furthermore many people tend to ignore this fact and try to power a high power white LED which requires about 3.5V from a 5V power supply. It will not work. But the two circuits before sure do!

Following this principle, basically any voltage regulator can be used as a constant current supply, but it is a rather poor solution.

Transistor and comparator.

More coming soon.

Hallo BroesIk heb de laatste update gedownload. Sindsdien blijf ik elke keer bij het opstarten van de widgets de vraag krijgen of ik de laatste update (die ik al heb) wil downloaden. Hoe kan ik hier van af komen?Mac OS10,5,6

Really nice post. What about non linear power supplies, any experience?

My experience with switch mode linear supplies for LED is rather small, it’s mostly limited by custom solutions. I posted an article about the linear ones because i thought there were many poor uses of high power LEDs with linear supplies on the Internet that could use the information. The range was all the way to dumb connecting of more white LEDs to the 3.3V rail of a computer power supply.

It has been confirmed that my article proved of use to some, at least. Well, my greatest success was to make some people understand why you cannot use a LM317 as a constant mode power supply for a white LED, all powered from 5V.

The switch mode subject is a very vast one, I could only discuss some typical solution. The field of switch mode supplies for LEDs is new and growing, with LEDs proving to be the right solution for lighting of the future. This is why the marked it rather full of products, some better, some trying to cut as many corners as possible in order to reduce the manufacturer costs and providing poor quality for the user.

If i will have time (a resource which seems so poorly available to me lately) I will write an article about driving LEDs with switch mode supplies that involve using hardware on a microcontroller, more exactly I have used PWM and ADC on microcontrollers to make some sort of software switch mode supply for LEDs.

Very informative, clear and well explained. Thank you.

Pingback: Linear Power LED power supplies | Circuit master

Pingback: Electronics-Lab.com Blog » Blog Archive » Linear LED power supplies

Nice site and great text.